Since their introduction some fifty years ago in North America, continuous flight auger (CFA) piles, also known as augercast piles, have become increasingly popular, as they can be considerably cheaper than alternative pile types. With proper planning and design, efficient equipment and experienced personnel, high production rates can be achieved.

Piles are available in sizes 0.3, 0.45, 0.6, and 0.75 m diameter, and exceptionally 0.9 m diameter. They can be constructed to depths in excess of 30 meters.

CFA Equipment Tools

The equipment normally comprises of:

a base machine with a fixed, hanging or swinging lead

an auger drive unit (usually hydraulic) with sufficient power to advance the continuous flight auger to the required depth with minimum decompression of the surrounding soil

continuous flight augers of the required length and diameter (small or large stem), equipped with auger cutting heads suitable for the material to be penetrated Installation process.

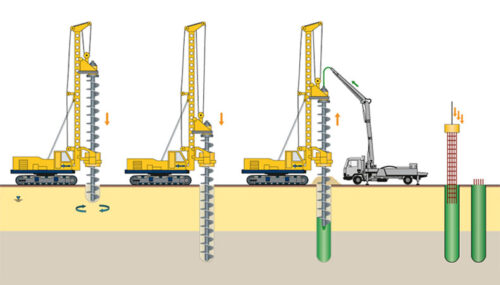

Installation

CFA piles are formed by drilling a continuous flight auger into the ground. The sides of the hole are supported at all times by the soil-filled auger, eliminating the need for temporary casing or betonies slurry. Upon reaching the required depth, sand-cement grout or concrete is pumped down the hollow stem as the auger is steadily withdrawn. Reinforcement is placed immediately after withdrawal of the auger.

The bearing capacity and settlement behavior of CFA piles is to a large extent influenced by the equipment used and the experience of the operator. The significance of these two aspects is often underestimate or overlooked at the design stage, but plays an important role for the performance of CFA piles.

Casting of pile base and shaft

When the auger has reached the required depth, the temporary plug (usually of wood or cork), which prevents soil from entering the hollow stem, has to be ejected. This is accomplished by slightly lifting the auger and injection of the concrete. During this phase soil decompression is almost unavoidable and it is common practice to reinsert the rotating auger while concrete is injected. This method minimizes to some degree decompression at the bottom of the pile but the quantitative effect is difficult to assess.

When the grout head is established, extraction is commenced at a rate, consistent with grout supply. Positive rotation of the auger is necessary to retain the drilling spoil and to ensure that the grout fills the entire pile cross section. The grout pressure must be sufficiently high and the auger must not be extracted too fast. Otherwise, drilling spoil can enter into the freshly placed grout, resulting in a soil-contaminated pile shaft.

Placing of reinforcement

In the case of a small stem diameter, which is most commonly used, the reinforcement must be installed after the auger has been withdrawn and while the grout or concrete is still fluid. The placement of a long reinforcement cage into an uncased hole can pose considerable practical problems and contaminate the concrete shaft with eroded soil. Therefore, it is important that the cage is stiff and properly welded In order to overcome the problem of proper placement of the reinforcement, augers with a larger stem are used and the reinforcement is installed inside before the extraction of the auger.